Key Insights

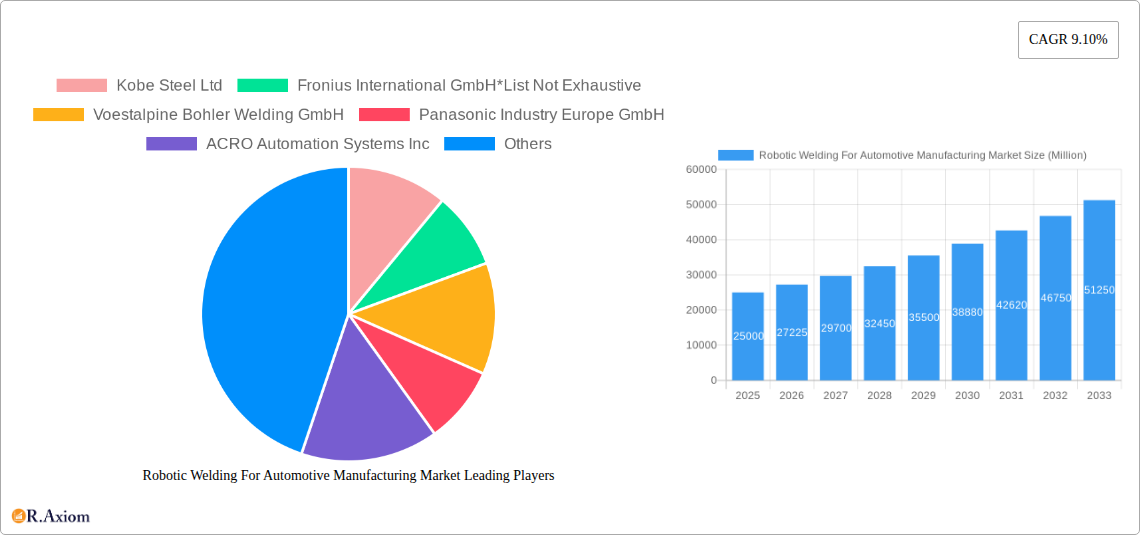

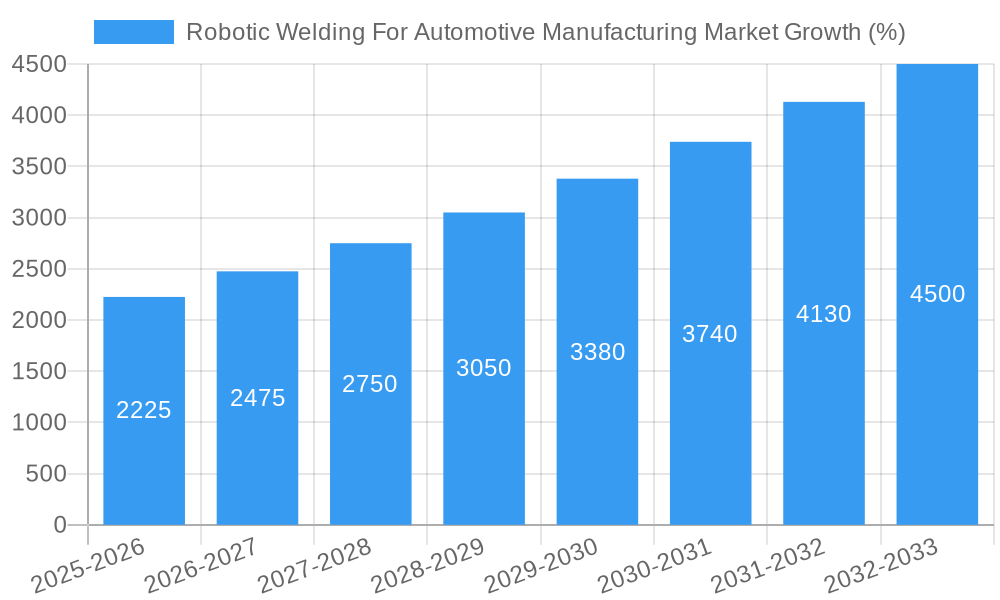

The Robotic Welding For Automotive Manufacturing market is experiencing robust growth, driven by the increasing automation in automotive production and the rising demand for high-quality, consistent welds. The market's Compound Annual Growth Rate (CAGR) of 9.10% from 2019 to 2024 suggests a significant expansion, and this trend is expected to continue through 2033. Key drivers include the need for improved productivity, enhanced weld quality, reduced labor costs, and the integration of Industry 4.0 technologies like advanced robotics and AI-powered welding systems. The adoption of resistance spot welding, resistance seam welding, and laser beam welding is prevalent, with resistance spot welding likely holding the largest market share due to its widespread applicability and cost-effectiveness. Leading companies like Kobe Steel, Fronius, Voestalpine, and Panasonic are driving innovation and expanding their market presence through technological advancements and strategic partnerships. While the automotive industry faces cyclical fluctuations, the long-term prospects for robotic welding remain positive, fueled by continuous improvements in welding technology and the growing focus on electric vehicle (EV) production, which requires highly precise and efficient welding processes.

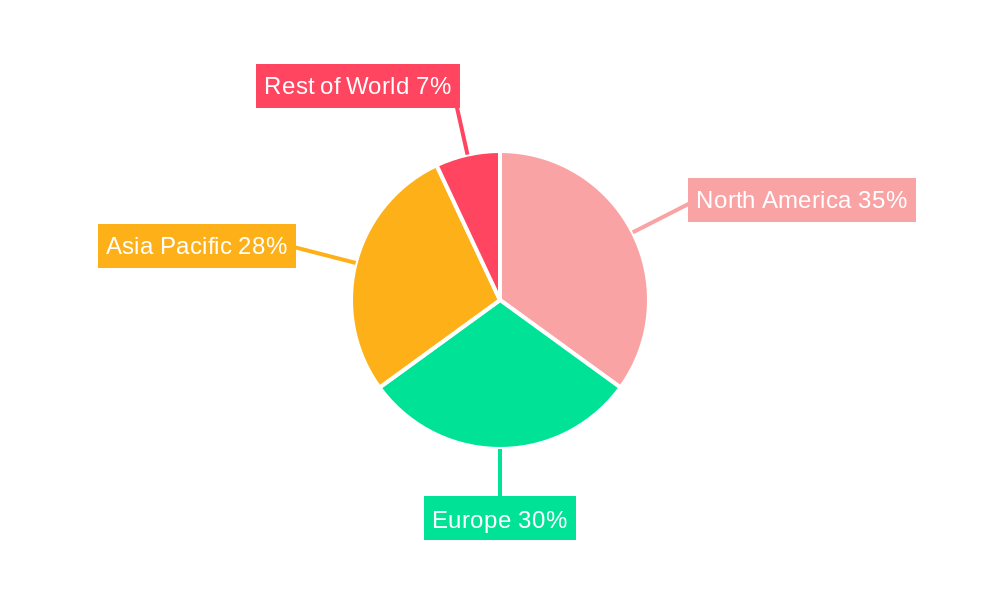

Geographic segmentation shows a strong presence across North America, Europe, and Asia-Pacific, with Asia-Pacific potentially exhibiting the highest growth due to the rapid expansion of automotive manufacturing in countries like China and India. However, North America and Europe are expected to maintain significant market shares due to established automotive industries and high adoption rates of advanced technologies. Market restraints include the high initial investment costs associated with robotic welding systems and the need for skilled technicians to operate and maintain them. Nevertheless, the long-term benefits of increased efficiency, improved quality, and reduced labor costs outweigh these challenges, ensuring sustained market growth. Considering a 2025 market size of, say, $25 billion (a reasonable estimate based on a CAGR of 9.10% over several years and considering industry reports), we project further substantial expansion in the coming years driven by the factors mentioned above.

Robotic Welding For Automotive Manufacturing Market: A Comprehensive Report (2019-2033)

This comprehensive report provides a detailed analysis of the Robotic Welding For Automotive Manufacturing Market, offering invaluable insights for stakeholders across the automotive and robotics industries. The study covers the period from 2019 to 2033, with 2025 as the base and estimated year. The report meticulously examines market trends, competitive landscapes, technological advancements, and future growth potential, enabling informed strategic decision-making. The market is expected to reach xx Million by 2033, exhibiting a CAGR of xx% during the forecast period (2025-2033).

Robotic Welding For Automotive Manufacturing Market Concentration & Innovation

The Robotic Welding For Automotive Manufacturing market exhibits a moderately concentrated landscape, with key players like Kobe Steel Ltd, Fronius International GmbH, Voestalpine Bohler Welding GmbH, Panasonic Industry Europe GmbH, ACRO Automation Systems Inc, Ador Welding Limited, Lincoln Electric Holdings Inc, Kawasaki Heavy Industries Ltd, Miller Electric Manufacturing LLC, RobotWorx, and Yaskawa Electric Corporation holding significant market share. Market concentration is further influenced by factors such as technological advancements, M&A activities, and regulatory changes. The market share of the top 5 players is estimated at xx%, indicating a competitive but not overly dominated landscape. Recent M&A activities, while not extensively documented in publicly available information, suggest ongoing consolidation efforts within the sector, with deal values ranging from xx Million to xx Million in recent years. Innovation is a key driver, with advancements in AI-powered welding systems and collaborative robotics shaping market dynamics. Regulatory frameworks focusing on safety and environmental compliance also play a significant role. The market experiences substitution pressures from traditional welding techniques, but the advantages of robotic welding in terms of speed, precision, and consistency are driving its continued growth. End-user trends toward automation and improved productivity are further bolstering market adoption.

Robotic Welding For Automotive Manufacturing Market Industry Trends & Insights

The Robotic Welding For Automotive Manufacturing market is experiencing robust growth driven by the increasing demand for automation in automotive manufacturing. The rising need for enhanced productivity, improved welding quality, and reduced labor costs are key factors fueling market expansion. Technological advancements such as AI-powered welding systems, collaborative robots (cobots), and advanced sensor technologies are significantly impacting market dynamics. The market penetration of robotic welding systems is increasing steadily, especially in developed regions with well-established automotive industries. Consumer preferences for high-quality, cost-effective vehicles are indirectly influencing the demand for efficient and precise robotic welding solutions. Competitive dynamics are characterized by intense competition among established players and the emergence of innovative startups offering cutting-edge solutions. The market's growth trajectory is projected to remain positive, with a significant contribution from emerging economies experiencing rapid industrialization. The CAGR for the forecast period is estimated to be xx%, reflecting the sustained demand and technological progress within the sector.

Dominant Markets & Segments in Robotic Welding For Automotive Manufacturing Market

The Robotic Welding For Automotive Manufacturing market exhibits strong regional dominance across several geographical areas. Among product segments, Resistance Spot Welding holds the largest market share globally, driven by its widespread adoption across automotive assembly lines. Resistance Seam Welding and Laser Beam Welding also represent significant market segments, with Laser Beam Welding showing higher growth potential due to its increased precision and suitability for complex welding tasks.

- Key Drivers for Resistance Spot Welding Dominance:

- Established technology and widespread adoption.

- Cost-effectiveness compared to other methods.

- Suited to high-volume production processes.

- Key Drivers for Laser Beam Welding Growth:

- Increasing demand for higher precision and quality.

- Ability to weld dissimilar materials.

- Superior performance in complex applications.

Regional Dominance: While specific data on regional dominance requires further market research, regions such as North America, Europe, and Asia-Pacific are expected to show significant market share and robust growth. Strong automotive manufacturing bases and government support for automation in these regions contribute to the high demand for robotic welding systems. Economic policies promoting industrial automation, coupled with robust infrastructure, further bolster market expansion.

Robotic Welding For Automotive Manufacturing Market Product Developments

Recent product innovations focus on improving the speed, precision, and adaptability of robotic welding systems. AI-powered welding systems enable self-learning and optimization capabilities, leading to improved weld quality and reduced cycle times. The integration of advanced sensor technologies provides real-time monitoring and control, enhancing overall system performance. These advancements cater to the evolving needs of automotive manufacturers, addressing demands for greater efficiency, flexibility, and precision in welding processes. The competitive advantage lies in delivering robust, reliable, and user-friendly systems that can integrate seamlessly into existing production lines.

Report Scope & Segmentation Analysis

This report segments the Robotic Welding For Automotive Manufacturing market primarily by product type:

Resistance Spot Welding: This segment represents a significant portion of the market due to its widespread application in automotive body assembly. The segment is characterized by moderate growth, driven by ongoing demand from established automotive manufacturers.

Resistance Seam Welding: This segment enjoys steady growth, driven by its application in sealing and joining sheet metal components. Market dynamics are influenced by the ongoing trend towards lighter vehicle designs.

Laser Beam Welding: This segment showcases the highest growth potential, fueled by the increasing demand for high-precision welding applications. The segment is characterized by the emergence of innovative technologies and ongoing R&D efforts.

Key Drivers of Robotic Welding For Automotive Manufacturing Market Growth

Several factors propel the growth of the Robotic Welding For Automotive Manufacturing market:

- Technological advancements: AI integration, advanced sensor technology, and collaborative robotics enhance efficiency and precision.

- Economic factors: The need for reduced labor costs and increased productivity is a significant driver.

- Government regulations: Environmental and safety standards drive the adoption of cleaner and more precise welding technologies.

Challenges in the Robotic Welding For Automotive Manufacturing Market Sector

Challenges hindering market growth include:

- High initial investment costs: The cost of purchasing and implementing robotic welding systems can be substantial, posing a barrier for smaller manufacturers.

- Supply chain disruptions: Global supply chain vulnerabilities can impact the availability of components and delay project timelines.

- Skilled labor shortages: A lack of qualified personnel to operate and maintain robotic welding systems can limit adoption.

Emerging Opportunities in Robotic Welding For Automotive Manufacturing Market

Emerging opportunities include:

- Expansion into emerging markets: Growing automotive production in developing economies presents significant expansion potential.

- Integration with Industry 4.0 technologies: Connecting robotic welding systems to broader smart manufacturing ecosystems can further enhance efficiency and data analysis capabilities.

- Development of specialized welding solutions: Catering to the unique demands of electric vehicles and other specialized automotive applications offers growth avenues.

Leading Players in the Robotic Welding For Automotive Manufacturing Market Market

- Kobe Steel Ltd

- Fronius International GmbH

- Voestalpine Bohler Welding GmbH

- Panasonic Industry Europe GmbH

- ACRO Automation Systems Inc

- Ador Welding Limited

- Lincoln Electric Holdings Inc

- Kawasaki Heavy Industries Ltd

- Miller Electric Manufacturing LLC

- RobotWorx

- Yaskawa Electric Corporation

Key Developments in Robotic Welding For Automotive Manufacturing Market Industry

- June 2022: Kawasaki Robotics partnered with Realtime Robotics to automate robot programming and control in spot welding, improving efficiency and reducing programming time.

- May 2021: Path Robotics secured USD 56.0 Million in funding for AI-powered expansion, demonstrating investor confidence in the future of robotic welding technology.

Strategic Outlook for Robotic Welding For Automotive Manufacturing Market Market

The Robotic Welding For Automotive Manufacturing market holds substantial growth potential driven by ongoing technological advancements, increasing automation demands within the automotive sector, and the rise of electric vehicles. Continued innovation in areas such as AI-powered welding, collaborative robots, and advanced sensor technologies will further propel market expansion. The focus on efficiency, precision, and reduced operational costs will continue to drive adoption across various automotive manufacturing segments globally. Expanding into emerging markets and integrating robotic welding systems with broader Industry 4.0 initiatives will present further lucrative opportunities for market players.

Robotic Welding For Automotive Manufacturing Market Segmentation

-

1. Product

- 1.1. Resistance Spot Welding

- 1.2. Resistance Seam Welding

- 1.3. Laser Beam Welding

Robotic Welding For Automotive Manufacturing Market Segmentation By Geography

- 1. North America

- 2. Europe

- 3. Asia Pacific

- 4. Rest of The World

Robotic Welding For Automotive Manufacturing Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 9.10% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Intensifying adoption of Industry 4.0

- 3.3. Market Restrains

- 3.3.1. Government Regulations on Storage

- 3.4. Market Trends

- 3.4.1. Electric Vehicles Will Augment the Demand for Robotic Welding

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Product

- 5.1.1. Resistance Spot Welding

- 5.1.2. Resistance Seam Welding

- 5.1.3. Laser Beam Welding

- 5.2. Market Analysis, Insights and Forecast - by Region

- 5.2.1. North America

- 5.2.2. Europe

- 5.2.3. Asia Pacific

- 5.2.4. Rest of The World

- 5.1. Market Analysis, Insights and Forecast - by Product

- 6. North America Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Product

- 6.1.1. Resistance Spot Welding

- 6.1.2. Resistance Seam Welding

- 6.1.3. Laser Beam Welding

- 6.1. Market Analysis, Insights and Forecast - by Product

- 7. Europe Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Product

- 7.1.1. Resistance Spot Welding

- 7.1.2. Resistance Seam Welding

- 7.1.3. Laser Beam Welding

- 7.1. Market Analysis, Insights and Forecast - by Product

- 8. Asia Pacific Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Product

- 8.1.1. Resistance Spot Welding

- 8.1.2. Resistance Seam Welding

- 8.1.3. Laser Beam Welding

- 8.1. Market Analysis, Insights and Forecast - by Product

- 9. Rest of The World Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Product

- 9.1.1. Resistance Spot Welding

- 9.1.2. Resistance Seam Welding

- 9.1.3. Laser Beam Welding

- 9.1. Market Analysis, Insights and Forecast - by Product

- 10. North America Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - By Country/Sub-region

- 10.1.1.

- 11. Europe Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 11.1. Market Analysis, Insights and Forecast - By Country/Sub-region

- 11.1.1.

- 12. Asia Pacific Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 12.1. Market Analysis, Insights and Forecast - By Country/Sub-region

- 12.1.1.

- 13. Rest of The World Robotic Welding For Automotive Manufacturing Market Analysis, Insights and Forecast, 2019-2031

- 13.1. Market Analysis, Insights and Forecast - By Country/Sub-region

- 13.1.1.

- 14. Competitive Analysis

- 14.1. Global Market Share Analysis 2024

- 14.2. Company Profiles

- 14.2.1 Kobe Steel Ltd

- 14.2.1.1. Overview

- 14.2.1.2. Products

- 14.2.1.3. SWOT Analysis

- 14.2.1.4. Recent Developments

- 14.2.1.5. Financials (Based on Availability)

- 14.2.2 Fronius International GmbH*List Not Exhaustive

- 14.2.2.1. Overview

- 14.2.2.2. Products

- 14.2.2.3. SWOT Analysis

- 14.2.2.4. Recent Developments

- 14.2.2.5. Financials (Based on Availability)

- 14.2.3 Voestalpine Bohler Welding GmbH

- 14.2.3.1. Overview

- 14.2.3.2. Products

- 14.2.3.3. SWOT Analysis

- 14.2.3.4. Recent Developments

- 14.2.3.5. Financials (Based on Availability)

- 14.2.4 Panasonic Industry Europe GmbH

- 14.2.4.1. Overview

- 14.2.4.2. Products

- 14.2.4.3. SWOT Analysis

- 14.2.4.4. Recent Developments

- 14.2.4.5. Financials (Based on Availability)

- 14.2.5 ACRO Automation Systems Inc

- 14.2.5.1. Overview

- 14.2.5.2. Products

- 14.2.5.3. SWOT Analysis

- 14.2.5.4. Recent Developments

- 14.2.5.5. Financials (Based on Availability)

- 14.2.6 Ador Welding Limited

- 14.2.6.1. Overview

- 14.2.6.2. Products

- 14.2.6.3. SWOT Analysis

- 14.2.6.4. Recent Developments

- 14.2.6.5. Financials (Based on Availability)

- 14.2.7 Lincoln Electric Holdings Inc

- 14.2.7.1. Overview

- 14.2.7.2. Products

- 14.2.7.3. SWOT Analysis

- 14.2.7.4. Recent Developments

- 14.2.7.5. Financials (Based on Availability)

- 14.2.8 Kawasaki Heavy Industries Ltd

- 14.2.8.1. Overview

- 14.2.8.2. Products

- 14.2.8.3. SWOT Analysis

- 14.2.8.4. Recent Developments

- 14.2.8.5. Financials (Based on Availability)

- 14.2.9 Miller Electric Manufacturing LLC

- 14.2.9.1. Overview

- 14.2.9.2. Products

- 14.2.9.3. SWOT Analysis

- 14.2.9.4. Recent Developments

- 14.2.9.5. Financials (Based on Availability)

- 14.2.10 RobotWorx

- 14.2.10.1. Overview

- 14.2.10.2. Products

- 14.2.10.3. SWOT Analysis

- 14.2.10.4. Recent Developments

- 14.2.10.5. Financials (Based on Availability)

- 14.2.11 Yaskawa Electric Corporation

- 14.2.11.1. Overview

- 14.2.11.2. Products

- 14.2.11.3. SWOT Analysis

- 14.2.11.4. Recent Developments

- 14.2.11.5. Financials (Based on Availability)

- 14.2.1 Kobe Steel Ltd

List of Figures

- Figure 1: Global Robotic Welding For Automotive Manufacturing Market Revenue Breakdown (Million, %) by Region 2024 & 2032

- Figure 2: North America Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 3: North America Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 4: Europe Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 5: Europe Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 6: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 7: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 8: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 9: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 10: North America Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Product 2024 & 2032

- Figure 11: North America Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Product 2024 & 2032

- Figure 12: North America Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 13: North America Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Product 2024 & 2032

- Figure 15: Europe Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Product 2024 & 2032

- Figure 16: Europe Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 17: Europe Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 18: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Product 2024 & 2032

- Figure 19: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Product 2024 & 2032

- Figure 20: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 21: Asia Pacific Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

- Figure 22: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Product 2024 & 2032

- Figure 23: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Product 2024 & 2032

- Figure 24: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue (Million), by Country 2024 & 2032

- Figure 25: Rest of The World Robotic Welding For Automotive Manufacturing Market Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Region 2019 & 2032

- Table 2: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Product 2019 & 2032

- Table 3: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Region 2019 & 2032

- Table 4: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 5: Robotic Welding For Automotive Manufacturing Market Revenue (Million) Forecast, by Application 2019 & 2032

- Table 6: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 7: Robotic Welding For Automotive Manufacturing Market Revenue (Million) Forecast, by Application 2019 & 2032

- Table 8: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 9: Robotic Welding For Automotive Manufacturing Market Revenue (Million) Forecast, by Application 2019 & 2032

- Table 10: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 11: Robotic Welding For Automotive Manufacturing Market Revenue (Million) Forecast, by Application 2019 & 2032

- Table 12: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Product 2019 & 2032

- Table 13: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 14: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Product 2019 & 2032

- Table 15: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 16: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Product 2019 & 2032

- Table 17: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

- Table 18: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Product 2019 & 2032

- Table 19: Global Robotic Welding For Automotive Manufacturing Market Revenue Million Forecast, by Country 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Robotic Welding For Automotive Manufacturing Market?

The projected CAGR is approximately 9.10%.

2. Which companies are prominent players in the Robotic Welding For Automotive Manufacturing Market?

Key companies in the market include Kobe Steel Ltd, Fronius International GmbH*List Not Exhaustive, Voestalpine Bohler Welding GmbH, Panasonic Industry Europe GmbH, ACRO Automation Systems Inc, Ador Welding Limited, Lincoln Electric Holdings Inc, Kawasaki Heavy Industries Ltd, Miller Electric Manufacturing LLC, RobotWorx, Yaskawa Electric Corporation.

3. What are the main segments of the Robotic Welding For Automotive Manufacturing Market?

The market segments include Product.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

Intensifying adoption of Industry 4.0.

6. What are the notable trends driving market growth?

Electric Vehicles Will Augment the Demand for Robotic Welding.

7. Are there any restraints impacting market growth?

Government Regulations on Storage.

8. Can you provide examples of recent developments in the market?

June 2022 - Kawasaki Robotics has teamed up with Realtime Robotics, a maker of autonomous motion planning for industrial robots, to automate the programming, implementation, and control of its industrial robots. Two BX100N Kawasaki robots are combined with Kawasaki Robotics' open programming platform, KRNX, and Realtime Robotics' breakthrough motion planning and collision avoidance software in the spot-welding demo cell.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Robotic Welding For Automotive Manufacturing Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Robotic Welding For Automotive Manufacturing Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Robotic Welding For Automotive Manufacturing Market?

To stay informed about further developments, trends, and reports in the Robotic Welding For Automotive Manufacturing Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence