Key Insights

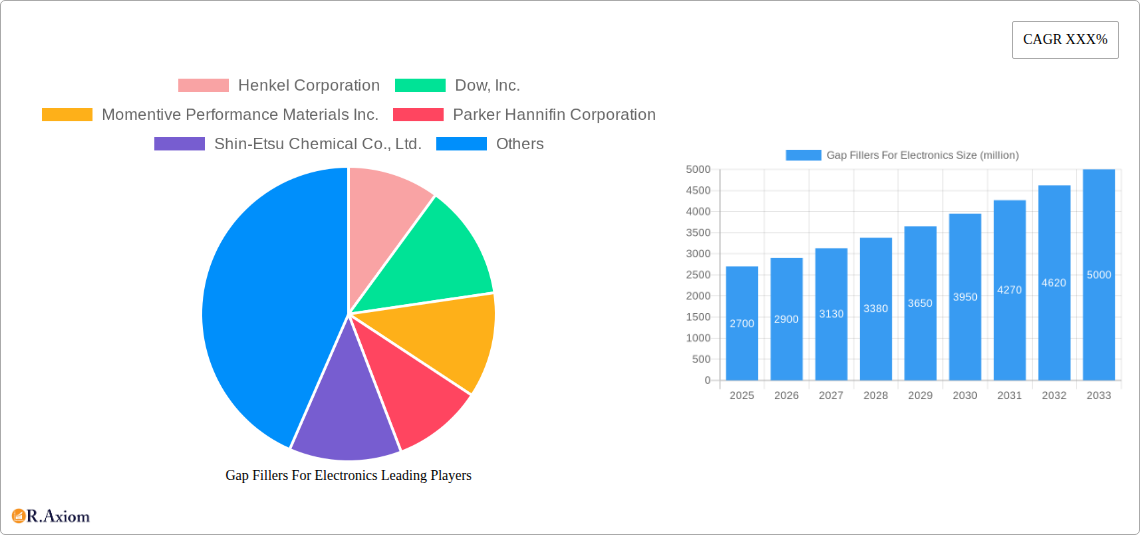

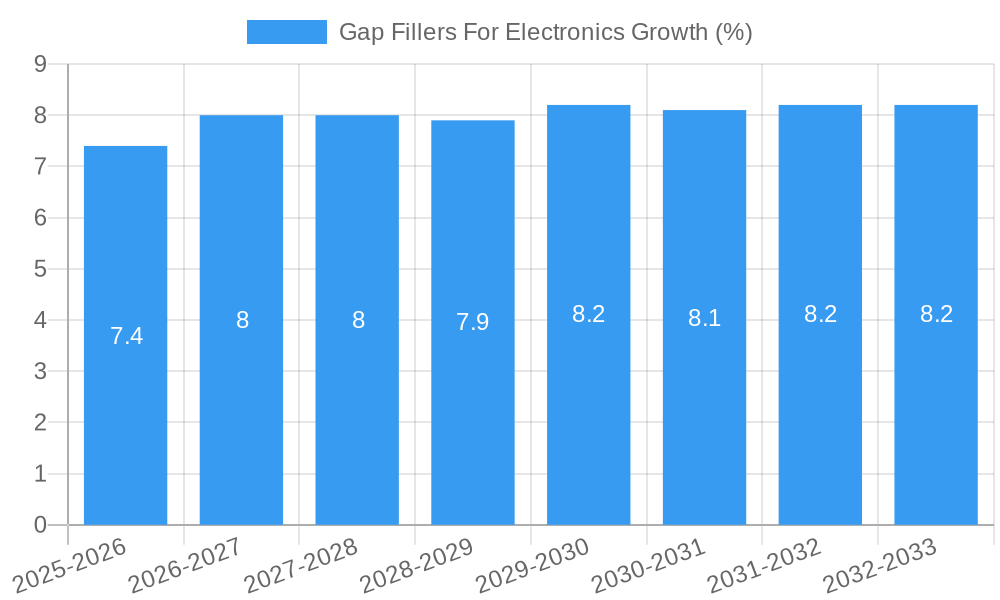

The global market for Gap Fillers for Electronics is poised for substantial growth, driven by the relentless expansion of the electronics industry and the increasing complexity of electronic devices. With a current market size estimated at approximately USD 2,500 million and a projected Compound Annual Growth Rate (CAGR) of around 7.5% to 8.5% over the forecast period (2025-2033), this segment is demonstrating robust momentum. The escalating demand for miniaturization, enhanced thermal management, and improved reliability in consumer electronics, automotive systems, and telecommunications equipment are key catalysts. Furthermore, the proliferation of 5G technology, the Internet of Things (IoT), and advanced driver-assistance systems (ADAS) are creating new avenues for gap filler adoption, particularly in applications requiring efficient heat dissipation and protection against environmental factors.

Key drivers fueling this market expansion include the critical need for thermal management solutions to prevent overheating in high-density electronic components, the growing adoption of flexible and wearable electronics necessitating conformable and protective materials, and the increasing sophistication of semiconductor and photonics packaging where precise gap filling is paramount for performance and longevity. While the market presents significant opportunities, potential restraints could emerge from volatile raw material prices, the development of alternative thermal management technologies, and stringent regulatory requirements related to material composition and environmental impact. However, the continuous innovation in material science, leading to the development of advanced gap fillers with superior thermal conductivity, electrical insulation, and mechanical properties, is expected to mitigate these challenges and sustain the upward trajectory of the market.

Gap Fillers For Electronics Market Concentration & Innovation

The global gap fillers for electronics market exhibits a moderate to high concentration, driven by the strong presence of key players such as Henkel Corporation, Dow, Inc., Momentive Performance Materials Inc., Shin-Etsu Chemical Co., Ltd., and 3M Company. These leading entities collectively hold a significant market share, estimated at over 70% as of the base year 2025. Innovation is a critical differentiator, with companies investing heavily in Research & Development to enhance thermal conductivity, dielectric properties, and ease of application for their gap filler solutions. Regulatory frameworks, particularly concerning environmental compliance and material safety (e.g., RoHS, REACH), are becoming increasingly stringent, influencing product formulations and manufacturing processes. The threat of product substitutes, such as thermal greases and phase change materials, exists, but gap fillers maintain their competitive edge due to their superior conformability and dispensing capabilities. End-user trends are leaning towards miniaturization, increased power density in electronic devices, and the growing adoption of flexible and wearable electronics, all of which necessitate advanced thermal management solutions. Mergers and acquisitions (M&A) activities are sporadic but significant, with deal values often ranging from tens of millions to hundreds of millions of dollars, aimed at consolidating market share and acquiring innovative technologies. For instance, the acquisition of a smaller specialized gap filler producer by a major chemical company in the historical period was valued at approximately xx million.

Gap Fillers For Electronics Industry Trends & Insights

The gap fillers for electronics market is poised for robust growth, projected to expand at a Compound Annual Growth Rate (CAGR) of over 8.5% during the forecast period of 2025–2033. This expansion is fueled by several intertwined industry trends and insights that are reshaping the landscape of thermal management solutions for electronic components.

One of the primary growth drivers is the relentless miniaturization and increasing power density of electronic devices. As processors and other components shrink in size while simultaneously generating more heat, effective thermal management becomes paramount to ensure device longevity, performance, and reliability. Gap fillers, with their unique ability to conform to irregular surfaces and fill microscopic voids, excel at bridging the thermal interface between heat-generating components and heat sinks, thereby facilitating efficient heat dissipation. This is particularly evident in the rapidly evolving semiconductor packaging segment, where advanced packaging techniques demand highly compliant and thermally conductive materials.

Technological disruptions are also playing a pivotal role. Innovations in material science are leading to the development of gap fillers with significantly improved thermal conductivity, often exceeding 5 W/mK, without compromising on electrical insulation properties. This advancement allows for thinner gap filler layers and more effective heat transfer, contributing to the overall performance enhancement of electronic systems. Furthermore, advancements in dispensing technologies, including automated robotic systems, are increasing the efficiency and precision of gap filler application, making them more attractive for high-volume manufacturing processes in sectors like automotive electronics and consumer electronics. The development of novel chemistries, such as advanced silicone formulations and hybrid polymer systems, is expanding the performance envelope of gap fillers to meet the stringent requirements of demanding applications like high-power servers and electric vehicle powertrains.

Consumer preferences are indirectly influencing the market through their demand for sleeker, more powerful, and energy-efficient electronic devices. The trend towards thinner laptops, smaller smartphones, and more compact gaming consoles necessitates the use of space-saving thermal management solutions like gap fillers. Moreover, the growing adoption of 5G technology and the proliferation of the Internet of Things (IoT) devices are creating new markets for gap fillers, as these applications often involve a dense integration of electronic components requiring effective thermal control.

Competitive dynamics within the industry are characterized by intense innovation and strategic partnerships. Companies are not only focused on developing superior products but also on optimizing their supply chains and offering customized solutions to meet specific customer needs. The market penetration of advanced gap filler materials is steadily increasing across various application segments, indicating a growing reliance on these materials for reliable thermal management. The historical period (2019-2024) witnessed significant R&D efforts and early adoption in high-growth sectors, setting the stage for sustained growth in the forecast period.

Dominant Markets & Segments in Gap Fillers For Electronics

The global gap fillers for electronics market is segmented by application and type, with certain segments demonstrating exceptional dominance driven by specific economic policies, infrastructural advancements, and evolving end-user demands.

Dominant Applications:

Electronics Assembly: This broad segment remains the cornerstone of the gap fillers market. The ever-increasing complexity and power density of consumer electronics, computing devices, and telecommunications equipment necessitate effective thermal management. The sheer volume of production in this sector makes it a consistently high-demand area for gap fillers. Economic policies promoting domestic manufacturing and technological innovation in electronics further bolster this segment.

Semiconductor Packaging: This is a rapidly growing and highly critical application. As semiconductor devices become smaller, more powerful, and integrated into advanced packages, the need for precise thermal management solutions to prevent overheating and ensure reliability is paramount. The growth in high-performance computing, artificial intelligence (AI), and 5G infrastructure directly fuels demand for sophisticated gap fillers in semiconductor packaging. Infrastructure development in high-tech manufacturing facilities further supports this segment's expansion.

Automotive Electronics: The automotive industry's transition towards electric vehicles (EVs) and advanced driver-assistance systems (ADAS) has significantly boosted the demand for gap fillers. EVs, with their complex battery management systems, power inverters, and onboard chargers, generate substantial heat. ADAS systems, incorporating numerous sensors and processors, also require efficient thermal dissipation. Government incentives for EV adoption and regulations mandating advanced safety features are key drivers here.

Dominant Types:

Silicone-Based Gap Fillers: These materials dominate the market due to their excellent thermal stability, flexibility, good dielectric properties, and wide operating temperature range. Their inherent resilience to moisture and chemicals makes them ideal for various environmental conditions encountered in electronics manufacturing. The established manufacturing processes and availability of raw materials contribute to their widespread adoption.

Epoxy-Based Gap Fillers: While typically less flexible than silicones, epoxy-based gap fillers offer superior mechanical strength and adhesion. They are often chosen for applications where robust structural integrity and high thermal conductivity are required. Their use is prevalent in applications demanding high reliability and resistance to harsh operating environments.

Graphite-Based Gap Fillers: With the increasing demand for ultra-high thermal conductivity, graphite-based gap fillers are gaining significant traction. These materials leverage the exceptional thermal properties of graphene and other carbon allotropes to achieve very high thermal performance, often exceeding 10 W/mK. Their application is growing in high-power density devices where standard gap fillers may not suffice.

The dominance of these segments is further amplified by ongoing research and development efforts focused on enhancing performance characteristics, such as higher thermal conductivity, improved electrical insulation, and greater durability. Advancements in dispensing technologies also play a crucial role in enabling the efficient and cost-effective application of gap fillers in high-volume manufacturing environments, solidifying the market position of these dominant segments.

Gap Fillers For Electronics Product Developments

Recent product developments in the gap fillers for electronics market have focused on enhancing thermal conductivity, improving application efficiency, and expanding material compatibility. Innovations include ultra-high thermal conductivity silicone and epoxy-based gap fillers exceeding 8 W/mK, designed for demanding applications like high-performance computing and electric vehicle power electronics. Advanced dispensing technologies are being integrated with these materials, enabling faster and more precise application in automated manufacturing lines. Furthermore, the development of low-outgassing and low-stress formulations caters to sensitive applications in aerospace and advanced semiconductor packaging, offering improved reliability and longevity for electronic components. These developments aim to provide superior thermal management solutions that are both high-performing and cost-effective.

Report Scope & Segmentation Analysis

This report provides a comprehensive analysis of the global gap fillers for electronics market, segmented by application and type. The Application segments include Electronics Assembly, Flip Chip Bonding, LCD Panel Assembly, Flexible Electronics, Photonics Packaging, Semiconductor Packaging, Automotive Electronics, and Others. Each segment is analyzed for its market size, projected growth, and competitive landscape. The Type segmentation encompasses Silicone-Based Gap Fillers, Polyurethane-Based Gap Fillers, Acrylic-Based Gap Fillers, Epoxy-Based Gap Fillers, Graphite-Based Gap Fillers, and Others. Growth projections and market penetration for each type are detailed, highlighting their respective strengths and areas of application. The analysis covers the historical period (2019-2024), base year (2025), and forecast period (2025-2033), offering insights into market dynamics, key drivers, and emerging opportunities across all defined segments.

Key Drivers of Gap Fillers For Electronics Growth

The growth of the gap fillers for electronics market is primarily driven by the escalating demand for effective thermal management solutions in increasingly compact and powerful electronic devices. The rapid advancements in the semiconductor industry, including higher processing power and miniaturization, necessitate materials that can efficiently dissipate heat. The burgeoning electric vehicle (EV) market, with its complex battery systems and power electronics, presents a significant growth avenue. Furthermore, the proliferation of 5G infrastructure and the Internet of Things (IoT) ecosystem are creating new applications and driving demand for advanced thermal interface materials. Government initiatives promoting technological innovation and sustainable energy solutions also indirectly support market expansion.

Challenges in the Gap Fillers For Electronics Sector

Despite the positive growth trajectory, the gap fillers for electronics sector faces several challenges. Stringent regulatory requirements regarding material composition and environmental impact can increase development and compliance costs for manufacturers. Fluctuations in raw material prices, particularly for specialized polymers and fillers, can impact profit margins and product pricing. The highly competitive landscape often leads to price pressures, making it difficult for smaller players to gain market share. Additionally, the need for highly customized solutions for niche applications can increase R&D expenses and lead times. Supply chain disruptions, as witnessed in recent global events, can also pose a significant challenge to timely product delivery.

Emerging Opportunities in Gap Fillers For Electronics

Emerging opportunities in the gap fillers for electronics market lie in the development of advanced materials with ultra-high thermal conductivity for next-generation power electronics and data centers. The growing adoption of flexible and wearable electronics presents a demand for highly conformable and mechanically robust gap fillers. The expansion of the aerospace and defense sectors, which require highly reliable thermal management solutions for critical systems, offers another lucrative avenue. Furthermore, the increasing focus on sustainability is driving demand for eco-friendly and recyclable gap filler materials. Innovations in additive manufacturing (3D printing) for customized gap filler structures also represent a significant future opportunity.

Leading Players in the Gap Fillers For Electronics Market

- Henkel Corporation

- Dow, Inc.

- Momentive Performance Materials Inc.

- Parker Hannifin Corporation

- Shin-Etsu Chemical Co., Ltd.

- Laird Performance Materials

- LORD Corporation

- 3M Company

- Wacker Chemie AG

- Master Bond Inc.

- Panasonic Corporation

- Bergquist Company

- Zymet, Inc.

- Electrolube Ltd.

- Chase Corporation

- SEKISUI POLYMATECH

- Timtronics

Key Developments in Gap Fillers For Electronics Industry

- 2023/2024: Increased investment in R&D for high-thermal-conductivity graphite-based gap fillers to meet the demands of 5G infrastructure and high-performance computing.

- 2023: Introduction of new low-viscosity, high-performance silicone gap fillers for automated dispensing in consumer electronics assembly.

- 2022: Strategic acquisition of a specialized thermal management materials company by a leading chemical conglomerate to expand product portfolio and market reach.

- 2021: Development of advanced epoxy-based gap fillers offering enhanced mechanical strength and thermal stability for automotive power electronics.

- 2020: Growing emphasis on developing environmentally friendly and REACH-compliant gap filler formulations in response to global regulatory trends.

Strategic Outlook for Gap Fillers For Electronics Market

The strategic outlook for the gap fillers for electronics market is highly positive, driven by continuous technological advancements and the increasing integration of electronics across diverse industries. The ongoing miniaturization trend and the demand for higher performance in devices will continue to fuel the need for superior thermal management solutions. Key growth catalysts include the expansion of the electric vehicle market, the roll-out of 5G networks, and the proliferation of smart devices. Companies that can innovate in material science to offer higher thermal conductivity, improved ease of application, and enhanced durability will be best positioned for success. Furthermore, strategic partnerships and targeted M&A activities will play a crucial role in consolidating market share and accessing new technologies, ensuring sustained growth and profitability in the coming years.

Gap Fillers For Electronics Segmentation

-

1. Application

- 1.1. Electronics Assembly

- 1.2. Flip Chip Bonding

- 1.3. LCD Panel Assembly

- 1.4. Flexible Electronics

- 1.5. Photonics Packaging

- 1.6. Semiconductor Packaging

- 1.7. Automotive Electronics

- 1.8. Others

-

2. Type

- 2.1. Silicone-Based Gap Fillers

- 2.2. Polyurethane-Based Gap Fillers

- 2.3. Acrylic-Based Gap Fillers

- 2.4. Epoxy-Based Gap Fillers

- 2.5. Graphite-Based Gap Fillers

- 2.6. Others

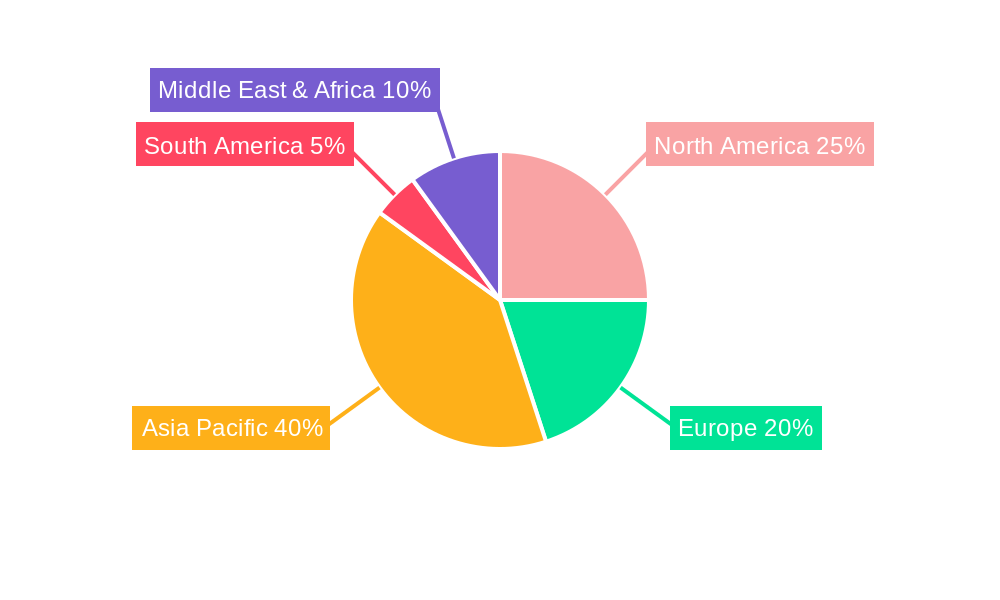

Gap Fillers For Electronics Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Gap Fillers For Electronics REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XXX% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Electronics Assembly

- 5.1.2. Flip Chip Bonding

- 5.1.3. LCD Panel Assembly

- 5.1.4. Flexible Electronics

- 5.1.5. Photonics Packaging

- 5.1.6. Semiconductor Packaging

- 5.1.7. Automotive Electronics

- 5.1.8. Others

- 5.2. Market Analysis, Insights and Forecast - by Type

- 5.2.1. Silicone-Based Gap Fillers

- 5.2.2. Polyurethane-Based Gap Fillers

- 5.2.3. Acrylic-Based Gap Fillers

- 5.2.4. Epoxy-Based Gap Fillers

- 5.2.5. Graphite-Based Gap Fillers

- 5.2.6. Others

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Electronics Assembly

- 6.1.2. Flip Chip Bonding

- 6.1.3. LCD Panel Assembly

- 6.1.4. Flexible Electronics

- 6.1.5. Photonics Packaging

- 6.1.6. Semiconductor Packaging

- 6.1.7. Automotive Electronics

- 6.1.8. Others

- 6.2. Market Analysis, Insights and Forecast - by Type

- 6.2.1. Silicone-Based Gap Fillers

- 6.2.2. Polyurethane-Based Gap Fillers

- 6.2.3. Acrylic-Based Gap Fillers

- 6.2.4. Epoxy-Based Gap Fillers

- 6.2.5. Graphite-Based Gap Fillers

- 6.2.6. Others

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Electronics Assembly

- 7.1.2. Flip Chip Bonding

- 7.1.3. LCD Panel Assembly

- 7.1.4. Flexible Electronics

- 7.1.5. Photonics Packaging

- 7.1.6. Semiconductor Packaging

- 7.1.7. Automotive Electronics

- 7.1.8. Others

- 7.2. Market Analysis, Insights and Forecast - by Type

- 7.2.1. Silicone-Based Gap Fillers

- 7.2.2. Polyurethane-Based Gap Fillers

- 7.2.3. Acrylic-Based Gap Fillers

- 7.2.4. Epoxy-Based Gap Fillers

- 7.2.5. Graphite-Based Gap Fillers

- 7.2.6. Others

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Electronics Assembly

- 8.1.2. Flip Chip Bonding

- 8.1.3. LCD Panel Assembly

- 8.1.4. Flexible Electronics

- 8.1.5. Photonics Packaging

- 8.1.6. Semiconductor Packaging

- 8.1.7. Automotive Electronics

- 8.1.8. Others

- 8.2. Market Analysis, Insights and Forecast - by Type

- 8.2.1. Silicone-Based Gap Fillers

- 8.2.2. Polyurethane-Based Gap Fillers

- 8.2.3. Acrylic-Based Gap Fillers

- 8.2.4. Epoxy-Based Gap Fillers

- 8.2.5. Graphite-Based Gap Fillers

- 8.2.6. Others

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Electronics Assembly

- 9.1.2. Flip Chip Bonding

- 9.1.3. LCD Panel Assembly

- 9.1.4. Flexible Electronics

- 9.1.5. Photonics Packaging

- 9.1.6. Semiconductor Packaging

- 9.1.7. Automotive Electronics

- 9.1.8. Others

- 9.2. Market Analysis, Insights and Forecast - by Type

- 9.2.1. Silicone-Based Gap Fillers

- 9.2.2. Polyurethane-Based Gap Fillers

- 9.2.3. Acrylic-Based Gap Fillers

- 9.2.4. Epoxy-Based Gap Fillers

- 9.2.5. Graphite-Based Gap Fillers

- 9.2.6. Others

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Gap Fillers For Electronics Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Electronics Assembly

- 10.1.2. Flip Chip Bonding

- 10.1.3. LCD Panel Assembly

- 10.1.4. Flexible Electronics

- 10.1.5. Photonics Packaging

- 10.1.6. Semiconductor Packaging

- 10.1.7. Automotive Electronics

- 10.1.8. Others

- 10.2. Market Analysis, Insights and Forecast - by Type

- 10.2.1. Silicone-Based Gap Fillers

- 10.2.2. Polyurethane-Based Gap Fillers

- 10.2.3. Acrylic-Based Gap Fillers

- 10.2.4. Epoxy-Based Gap Fillers

- 10.2.5. Graphite-Based Gap Fillers

- 10.2.6. Others

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Henkel Corporation

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Dow Inc.

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Momentive Performance Materials Inc.

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Parker Hannifin Corporation

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Shin-Etsu Chemical Co. Ltd.

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Laird Performance Materials

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 LORD Corporation

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 3M Company

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Wacker Chemie AG

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Master Bond Inc.

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Panasonic Corporation

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Bergquist Company

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Zymet Inc.

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Electrolube Ltd.

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 Chase Corporation

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 SEKISUI POLYMATECH

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.17 Timtronics

- 11.2.17.1. Overview

- 11.2.17.2. Products

- 11.2.17.3. SWOT Analysis

- 11.2.17.4. Recent Developments

- 11.2.17.5. Financials (Based on Availability)

- 11.2.1 Henkel Corporation

List of Figures

- Figure 1: Global Gap Fillers For Electronics Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Gap Fillers For Electronics Revenue (million), by Application 2024 & 2032

- Figure 3: North America Gap Fillers For Electronics Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Gap Fillers For Electronics Revenue (million), by Type 2024 & 2032

- Figure 5: North America Gap Fillers For Electronics Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America Gap Fillers For Electronics Revenue (million), by Country 2024 & 2032

- Figure 7: North America Gap Fillers For Electronics Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Gap Fillers For Electronics Revenue (million), by Application 2024 & 2032

- Figure 9: South America Gap Fillers For Electronics Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Gap Fillers For Electronics Revenue (million), by Type 2024 & 2032

- Figure 11: South America Gap Fillers For Electronics Revenue Share (%), by Type 2024 & 2032

- Figure 12: South America Gap Fillers For Electronics Revenue (million), by Country 2024 & 2032

- Figure 13: South America Gap Fillers For Electronics Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Gap Fillers For Electronics Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Gap Fillers For Electronics Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Gap Fillers For Electronics Revenue (million), by Type 2024 & 2032

- Figure 17: Europe Gap Fillers For Electronics Revenue Share (%), by Type 2024 & 2032

- Figure 18: Europe Gap Fillers For Electronics Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Gap Fillers For Electronics Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Gap Fillers For Electronics Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Gap Fillers For Electronics Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Gap Fillers For Electronics Revenue (million), by Type 2024 & 2032

- Figure 23: Middle East & Africa Gap Fillers For Electronics Revenue Share (%), by Type 2024 & 2032

- Figure 24: Middle East & Africa Gap Fillers For Electronics Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Gap Fillers For Electronics Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Gap Fillers For Electronics Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Gap Fillers For Electronics Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Gap Fillers For Electronics Revenue (million), by Type 2024 & 2032

- Figure 29: Asia Pacific Gap Fillers For Electronics Revenue Share (%), by Type 2024 & 2032

- Figure 30: Asia Pacific Gap Fillers For Electronics Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Gap Fillers For Electronics Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Gap Fillers For Electronics Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global Gap Fillers For Electronics Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 7: Global Gap Fillers For Electronics Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 13: Global Gap Fillers For Electronics Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 19: Global Gap Fillers For Electronics Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 31: Global Gap Fillers For Electronics Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Gap Fillers For Electronics Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Gap Fillers For Electronics Revenue million Forecast, by Type 2019 & 2032

- Table 40: Global Gap Fillers For Electronics Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Gap Fillers For Electronics Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Gap Fillers For Electronics?

The projected CAGR is approximately XXX%.

2. Which companies are prominent players in the Gap Fillers For Electronics?

Key companies in the market include Henkel Corporation, Dow, Inc., Momentive Performance Materials Inc., Parker Hannifin Corporation, Shin-Etsu Chemical Co., Ltd., Laird Performance Materials, LORD Corporation, 3M Company, Wacker Chemie AG, Master Bond Inc., Panasonic Corporation, Bergquist Company, Zymet, Inc., Electrolube Ltd., Chase Corporation, SEKISUI POLYMATECH, Timtronics.

3. What are the main segments of the Gap Fillers For Electronics?

The market segments include Application, Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4250.00, USD 6375.00, and USD 8500.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Gap Fillers For Electronics," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Gap Fillers For Electronics report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Gap Fillers For Electronics?

To stay informed about further developments, trends, and reports in the Gap Fillers For Electronics, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence